IRU

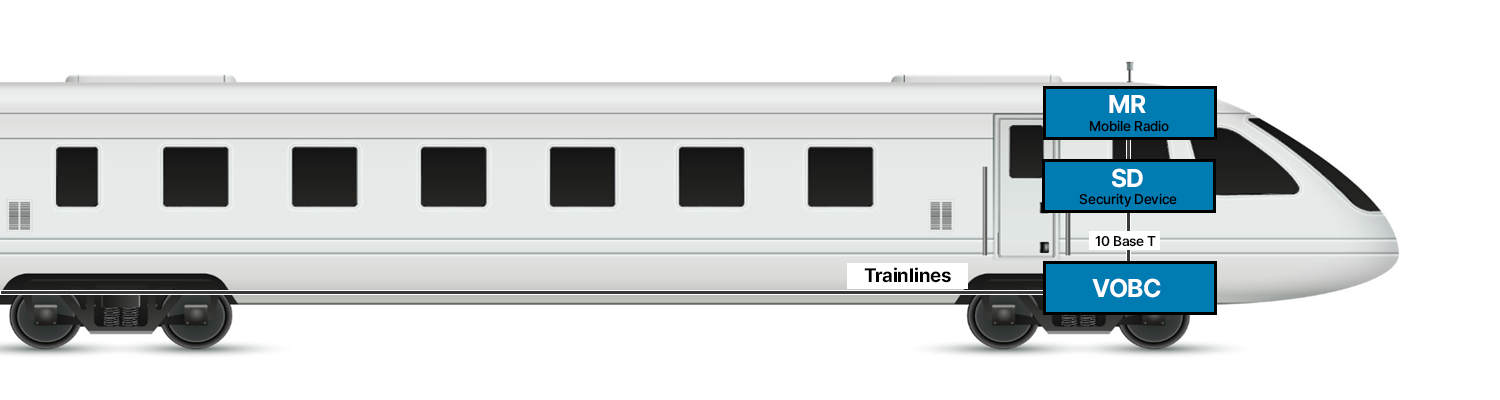

The Interface Relay Unit (IRU) is a sub-device of the train control system responsible for the interface of vital information between the vehicle system and the train control system.

To enhance operational efficiency,

modern train control systems in urban railways are introducing advanced train control devices supporting DTO (Driverless Train Operation) or UTO (Unattended Train Operation).

The localization of key components of IRU, including relays, which are essential devices of the train control system,

is crucial for fostering parts manufacturers and enhancing domestic technological competitiveness.

NB Solution Co., Ltd. succeeded in independently producing IRUs and relays through relentless efforts from June 2017 to May 2019.

IRUs and IRU relays are designed with an efficient structure for convenient fault diagnosis and repair.

Additionally, we have developed a portable IRU tester for easy IRU diagnosis and an IRU relay tester for diagnosing IRU relays.

Necessity of Product Development

- All IRUs for train control systems in Korea are foreign-made, resulting in high dependence on overseas technology.

- There are currently no domestically produced IRU products for train control systems.

- High dependence on foreign technology leads to excessive costs and time for spare parts procurement and maintenance by urban railway operators.

- The discontinuation of core relays and components may cause maintenance and operational difficulties for urban railway operators.

- Developing IRUs and IRU relays, the core components of train control systems, is essential for enhancing domestic technological competitiveness.

Development Contents

- Design of IRU device structure for easy maintenance (internal and external structure)

- Development of three types of IRU boards (relay board, filter board, interface board)

- Design and production of test equipment and hardware for testing the developed IRU device functions

- Design and implementation of software for testing the functions of the developed IRU device

- Production of relay press molds and injection molds for IRUs, welding of crossbar contacts for springs, coil production for relays, and design and production of relay sockets

- Design and production of relay testers for electrical characteristic tests of IRU relays

Advantages

1. Localization of Small Relays for Railway Vehicles

- Enhancement of repair and operation efficiency through localization of IRUs, relays, testers, and relay testers

2. Installation of Relay Log Storage Device

- Equipped with a storage device that saves internal relay logs to check operation counts, statuses, and history of relays for analyzing causes during malfunctions

3. Improvement of IRU Case Structure

- Convenient disassembly and assembly for repair by adopting a front-open structure with self ON/OFF function, making it easy to replace faulty relays

4. Structural Improvement for Real-time Operation Status Confirmation

- Real-time confirmation of operation status by placing a relay operation status display window on the front of the IRU

Expected Results

- Acquisition of core signal system technology

- Technology independence and cost competitiveness

- Expansion of overseas export channels

- Easy maintenance

- Cost reduction for customers

Devices

- Developed as a front-open type for easy maintenance, unlike foreign products

- Consists of three boards: relay board, filter board, and interface board

- Front panel arrangement of relays (direct replacement of relays after front opening)

- Real-time monitoring of relay status via front LED

- Logging of relay operation status (minimum of 3 months)

- Connection of maintenance computer to acquire and analyze logging information for checking relay status and operation history

▶Interface Relay Unit (IRU)

- All input/output and normal operation test device for IRU devices

- Cable connection and relay status check

- Confirmation of operation status of IRU relays

- Possible cable connection and operation status check for foreign IRU devices

- Automatic test function and report generation function

- Primary maintenance check device for IRU devices

- Movable for inspection and operation confirmation of IRU on each vehicle

- Planned for future upgrade to a more convenient mobile structure

▶IRU Tester

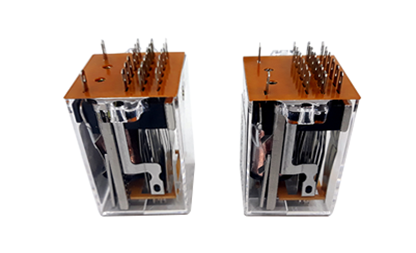

- DC 24V and 100V relays for IRU

- Interface with the train signal device is through DC 24V relays for input/output

- Interface with the vehicle system is through DC 100V relays for input/output

- Two contacts of the relay are used for relay status information logging

- Logging information through two contacts is stored in the memory of the IRU device

- Planned for future upgrade to be used in other relays besides IRU

▶Relay (24V / 100V)